Here are some important Issues and Fixes from the first batch TTSH pcbs (delivered around March 2014)

(page links/anchors)

- pcb silkscreen failure for powersupply

- Hum issue on Speaker and more

- Noise "distorted"

- Clock bleed on VCO pitch

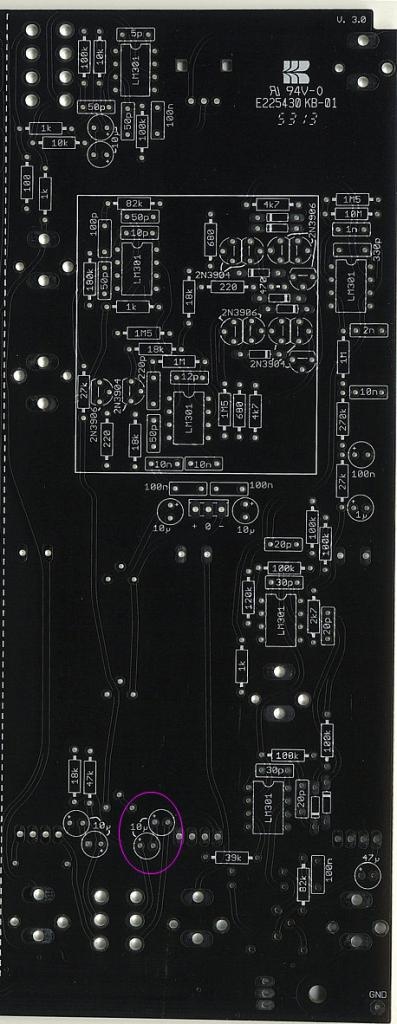

- wrong Silkscreen for matched pairs

- wrong Silkscreen or polarity for Capaciator C20

- VCO Bleed - Regulator

- not all LEDs are working

Resolution:

= tested

= untested

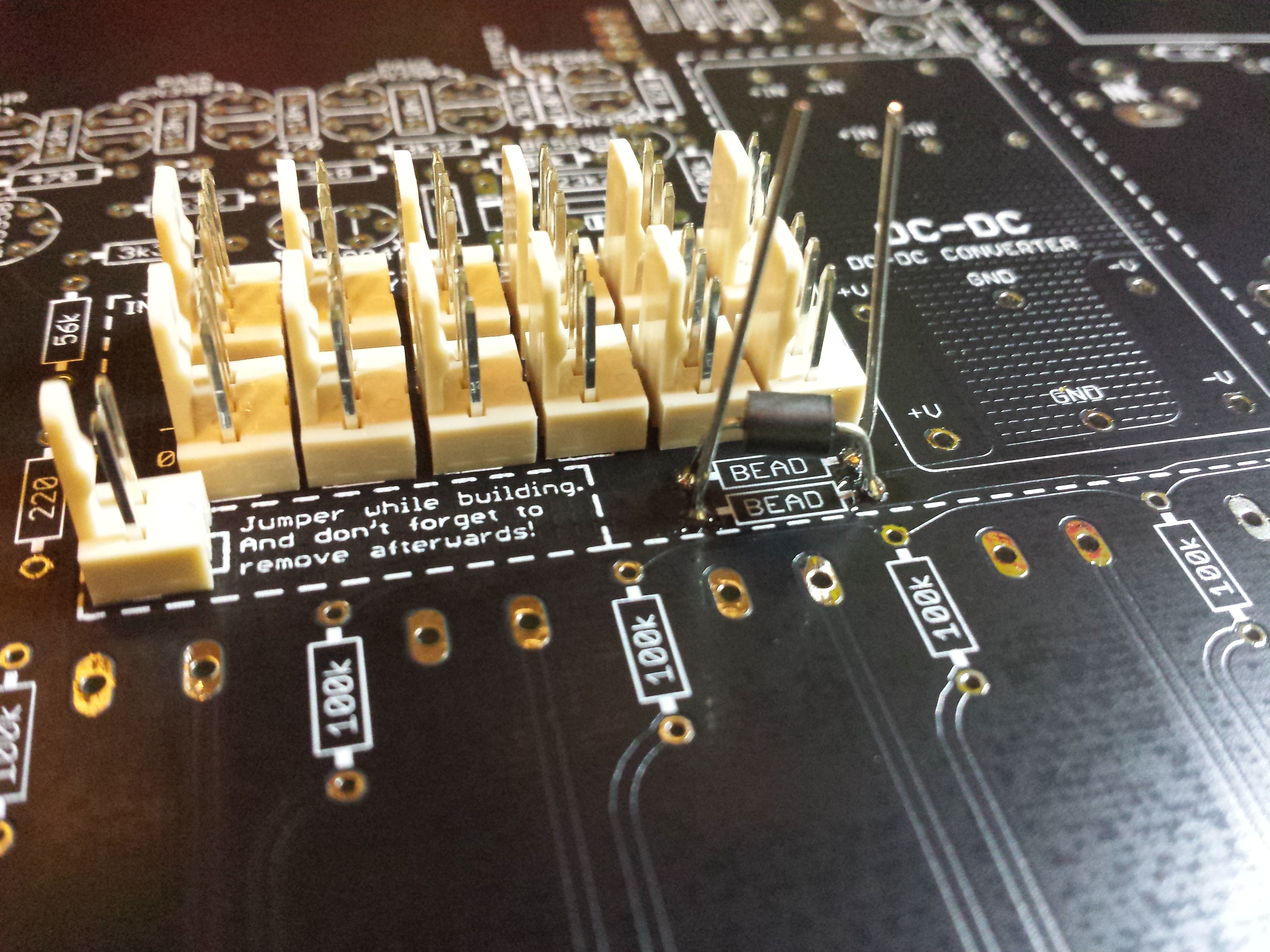

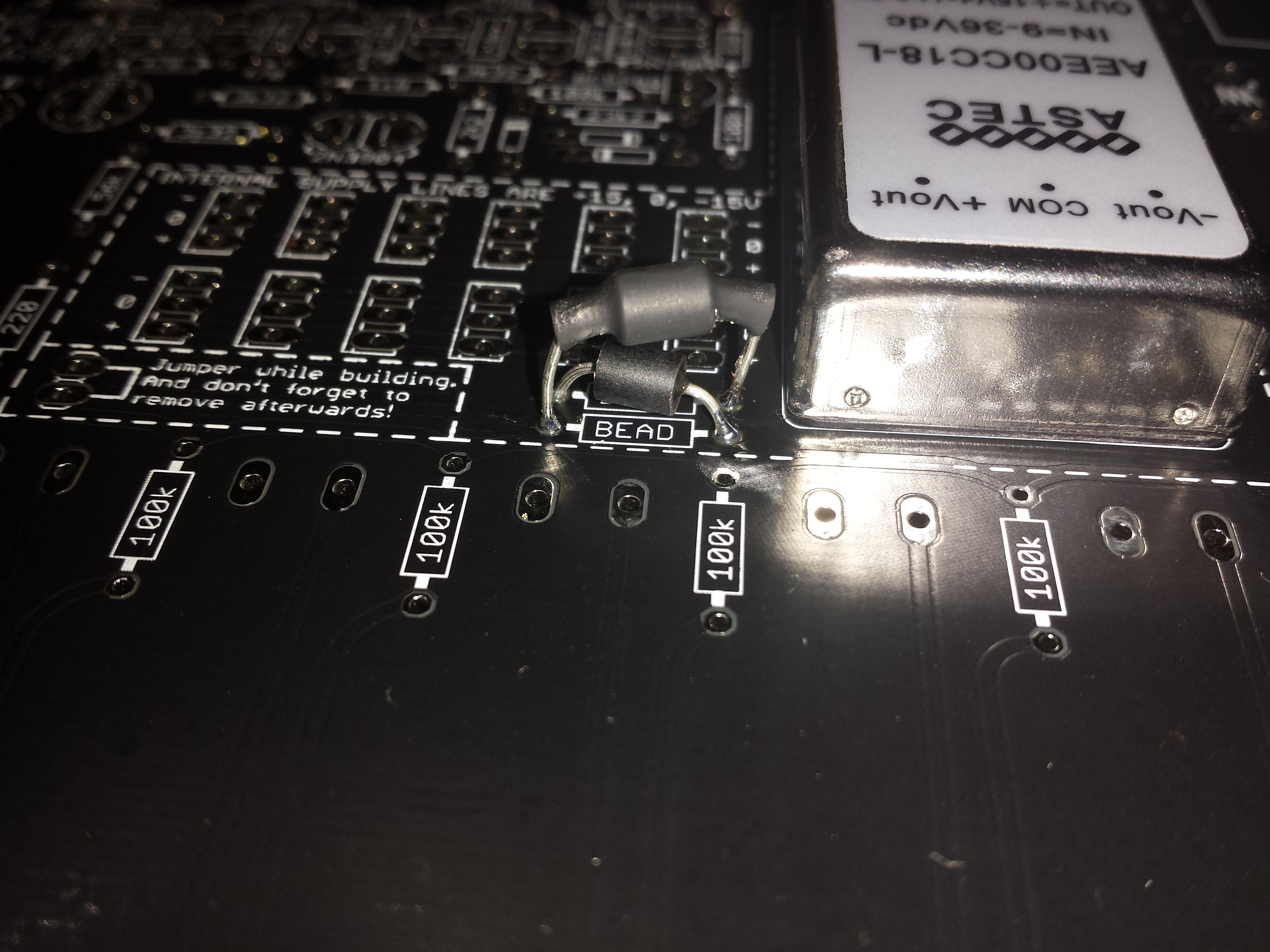

FIX for pcb silkscreen failure for powersupply

cross one Ferrite on top pcb side - the ferrite on other pcb site (not shown here)

other way:

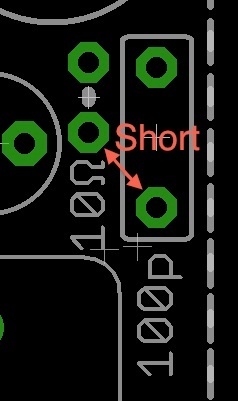

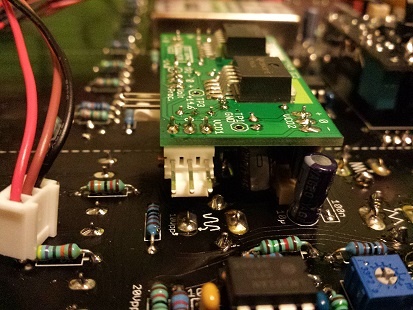

FIX for Hum issue on Speaker:

This Issue occurs by using the internal DC-DC Adapter,

FIX: short out the 10Ω resistor and the 100p capacitor in the PSU section. E.g. just make a small bridge between the pad close to 10Ω and 100p as in the attached picture.

further use RG174 cables or shielded microphone cable for offboard wiring.

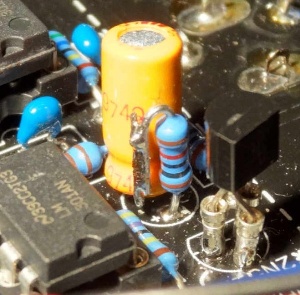

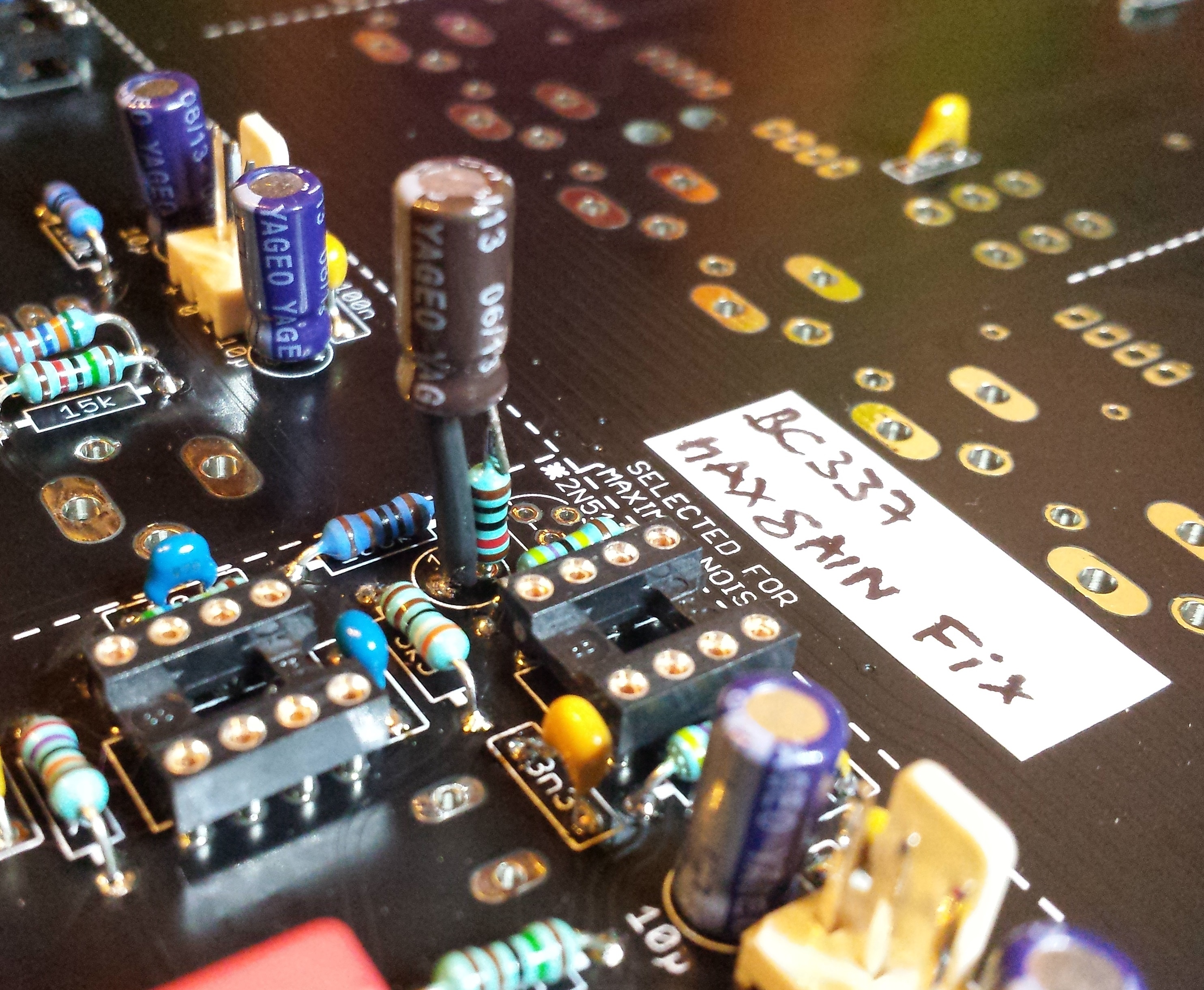

FIX for distorted Noise.

leave out the 2n5172 - use a bc337, - bend right leg to top, solder a 10K resistor in series to the 1uF cap.

Option A (from nordcore)

Option B: (from me and confirmed)

other working solution to connect a 10K resistor to the cap (after soldering, use shrinktube for cap and resistor housing )

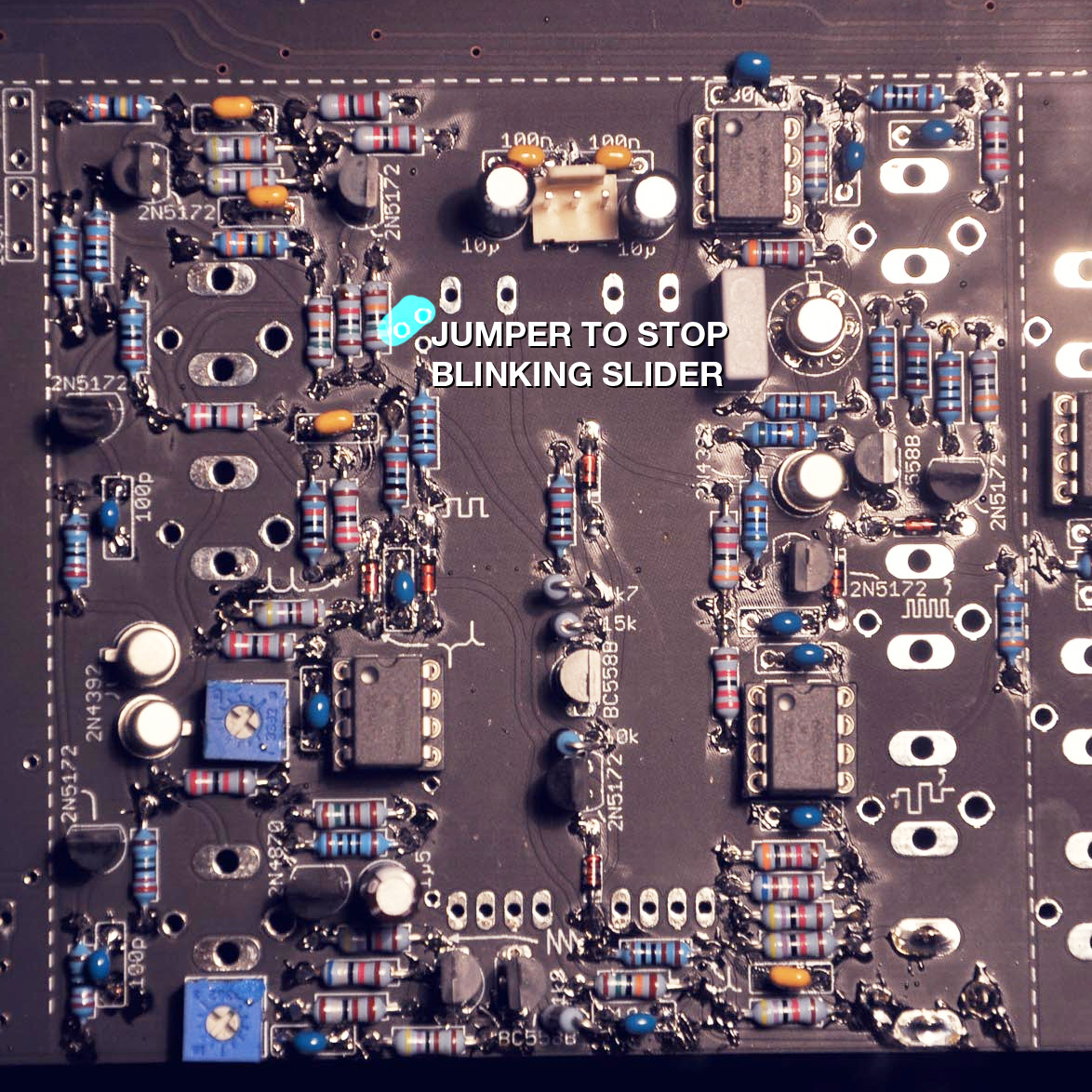

FIX for Clock bleed on VCO pitch

at the moment 2 steps to fix the Issue - (both together must used to fix the Issue)

First Step - tested solution : leave out the 2n5172 in clock section (led driver for blinken lights), bridge 2 solder holes..

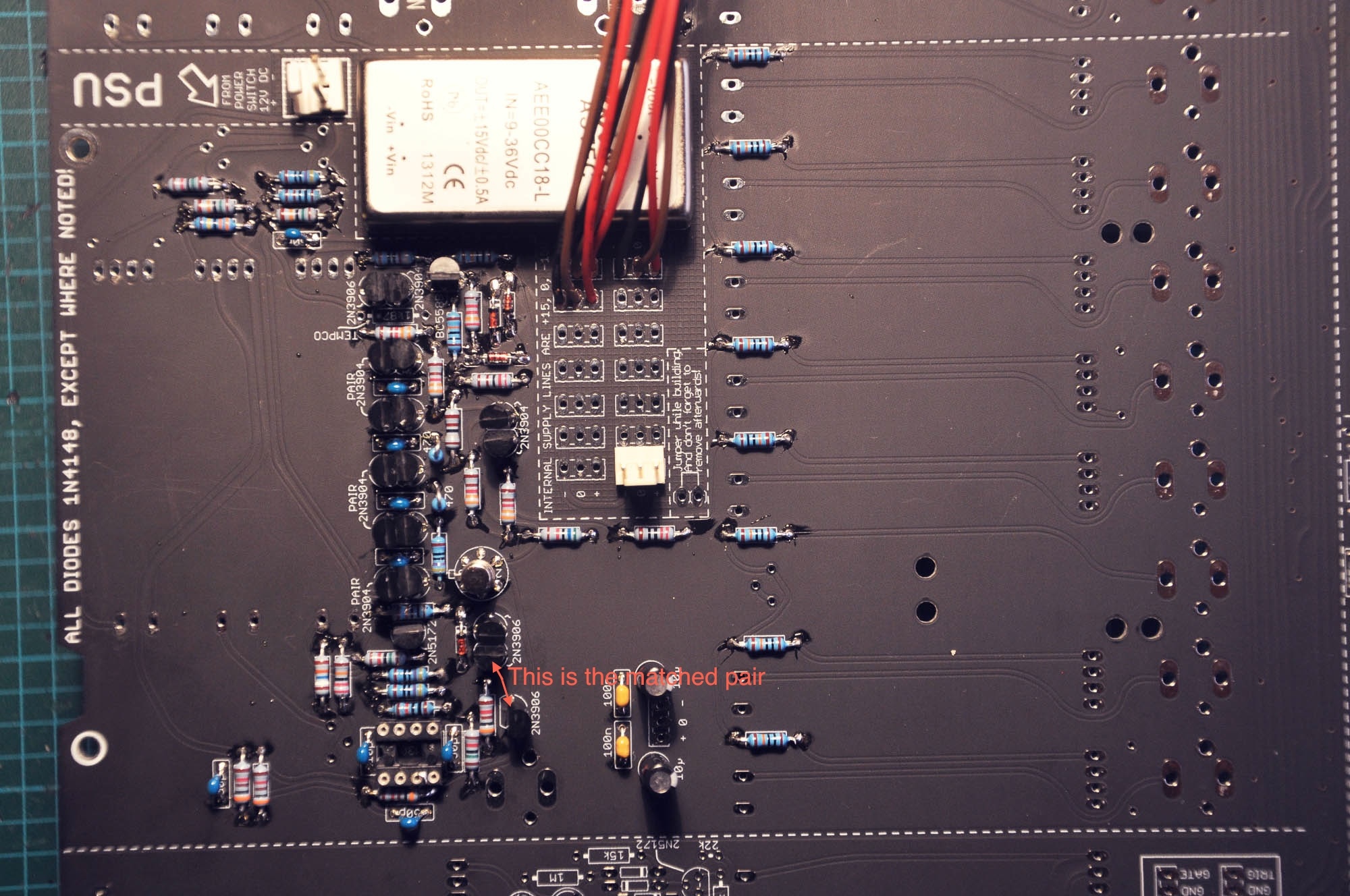

FIX for wrong Silkscreen for matched pairs Transistors in Filter section

the top 2n3906 is unmatched, you have to take 3 matched transistors if you´re not really sure about it.

FIX for wrong silkscreen or polarity for capaciator C20 in RINGMOD section  (untested by me)

(untested by me)

change the polarity of C20 10µF elecrolytics (its the right hand capaciator)

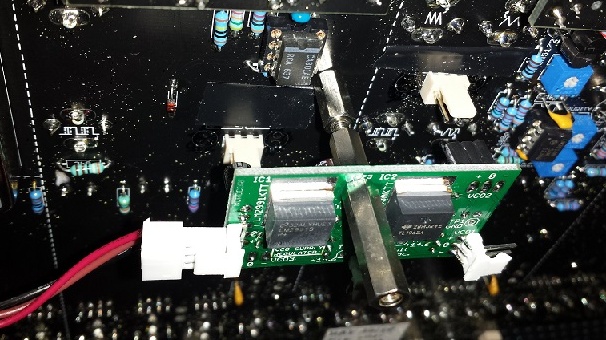

VCO Regulator:

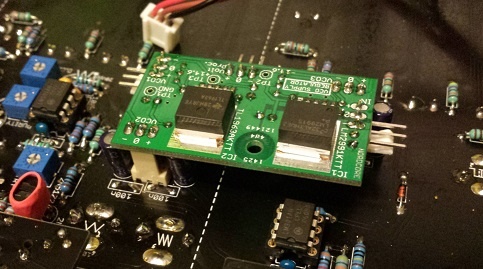

due to VCO Bleed issues, Nordcore from muffwiggler sales VCO Regulator pcbs, this fix this issue. approved

- build the VCO regulator

- desolder or cut the MLCC 100N from the power inputs on all 3vcos and from voltage processor, the 10uF caps can leave out too (but its okay to have this)

- drill a hole in pcb to mount by a 10/12mm spacer the pcb.

- put a further spacer on the 10/12mm spacer for calibrating the VCO regulator (dont connect the regulator to the vco header yet.

- connect only power input to regulator and set it to 14,6V (TP1+ TP2, TP1+TP3)

- unmount the second spacer and place the regulator in MTA header for final calibration/further tesing/building.

Issue: not all LED´s are working

Solution: turn the Trimmer LED- trimmer in the left bottom corner (frontpanel view)

(in my case LEDs dont glow in VCA section, otherwise connect the 470R to right (issue occurs by using Hum bug fix, in result no ground for LED´s in noise and left amp section )