...

Troubleshooting knowledge

...

i runned in some difficult erros in some TTSHs, here are my experiences

for unknown issues/Errors check this page: useful Documentation for Troubleshooting

| Knowledge number | symptom | Probable error source | Probability of occurrence | pre check | testing | workaround | fix | lessons learned |

|---|---|---|---|---|---|---|---|---|

| TTSH-1 | VCO bleed (usage of frequency slider from one OSC influenced other VCOs frequency or Frequency range isn´t good enough or screaming VCO - weird frequency / instable Frequency | LFO/VCO switch (LF switch) | 80% | insert a stable v/oct signal (doublecheck with other devices your v/oct signal) | press/push/wiggle the LF switch, if you hear or measure a better result -> | heat up the 6 switch pins | normally a resolder/heatup fix the issue | the switch pins must be soldered with other soldercore or better heated/other solder tip. |

| TTSH-2 | all Slider LEDs are off | Trimmer, LED Driver | turn on the frontpanel (left hand) the LED trimmer clockwise, check on the frontpanel side on the empty IC socket next that you bridged pin 6+7 and no IC is plugged inside the socket. if not fixed: measure on the 5 pole powerheader all voltages | n/a | dont forget the jumper/bridge on pin 6-7 | |||

| TTSH-3 | few Slider LEDs are off | Trimmer, LED Driver | 50% | turn on the frontpanel (left hand) the LED trimmer clockwise, the TTSH LEDs are connected in 6? chains and in each chain are all slider LEDs in series - so you must check the correct LED polarisation (you can see the cathode/anode without demounting) | swap the LED to correct orientation | dont trust machines/roboter | ||

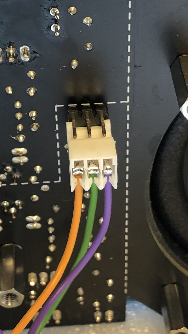

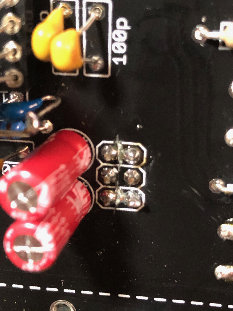

| TTSH-4 | all VCOs dont work | VCO 4027 boards | 10% | are the VCO subboards correct mounted ? (check the board connectors) are the CA3046 ICs inside ? check the soldering of the board connectors | solder all VCO conenctor pins before mounting the silders, add the CA3046 while mounting the connectors to the subboards | |||

| TTSH-5 | cant get a VCO sine wave in trimming/calibration process. (you get only a triangle) | VCO-2 section | 80% | check OP-amp orientation check J-FET (2N3954) instead 2N3958 | oscilloscope shows at the TRI out a Triangle - if not fix it before. | check the symmetry at first for the triangle, use gain to setup 10v then use the offset to bend the triangle spikes - they must form a corner in combination with purity. setup again 10v. its not a easy job - try it again - the trick is the combination of offset and gain not the purity ! | before you swap the 2N3954 try other ways as before by trimming the 4 trimmers , many guys swapped the working jfets.. | |

| TTSH-6 | ttsh works as a drone synth (by usage of cv/gate - the ttsh plays always sound instead of note on/off control) | 80% | check your silder settings - at the VCA output mixer - only VCA output instead of VCF or VCF and VCF. | read the usermanual | ||||

| TTSH-7 | by usage of the reverb function, a hum/noise occurs | 80 | see known issues - in/out silksceen is wrong check your noise is off check the wiring | use double or triple shielded cable with good RCA connectors the reverb distance must around 10cm or more from pcb to minimize the risk of EMV to the tank. check the grounding of signal input in the reverb, input and output must be grounded. check the cable with a rectifier test, check the soldering of the RCA connectors on the ttsh pcb. make sure you have the correct reverb type (grounding and impedance) | reverbs are very sensitive for EMV* | |||

| TTSH-8 | ADSR Release time opens the VCA and at 20fader way, the releasetime is too long | 50 | check all parts for correct value, check my pictures subpage | replace the 2N5460 or 2N4392 | test all trannys before soldering | |||

| TTSH-9 | sound from speakers - without OSCs enabled/installed | 30 | if the 10R resistors in the Amplifiers are hot or the MJE172 are hot, check the orientation of the MJE172 - the unlabeled side is at the white marker from the PCB. AND you have a short or defect opamp on your TTSH, which blows your MJE172 and the 10R resistors within 30seconds. you have to use a Bench power supply with current limiter, otherwise you freeze again the MJE172. you can cut at the 1UF elks the 6 pol power header - and connect it later with PC jumpers or use resistors legs to bridge the -15715V rails. | |||||

| TTSH-10 | power separation - in case of POWER FAILURES or shorts | use a Labor bench with current limiter. | separate the Sections, by cutting the traces. |

Gallery

check also the rev.3 buildguide pictures with HQ pictures ( thank you Björn Verbruggen)

...