Status: FINISHED

Startdate: 21.Dec.2016

Duedate: 31.Dec.2016

last update 06 March 2019 Mouser BOM project updated

Manufacture link: http://thehumancomparator.net/

due to changes in my webhosting (rootserver) costs for RAM/Backup and my worktime in Adminstration of the Server & Web Application Server it would be very helpful to use my paypal gift function, thank you

This guide is complete yet ( last update on 18.Jan.2017)

please check my rev.2 build guide and hardcorebuildguide, gatebooster pages, that gives you more infos and knowledge.

the TTSH project isn`t for beginners !

Feel free to register a account for free, you can comment, export pages, you stay informed with pageupdates by email.

send messages to me and other users with the share page function ( in top right corner)

you can send me a message if you want edit my pages, i´m looking for supporters.

further i´m looking for authors too, please contact me

Table of Contents

Trusted Builders:

| Name | Region | Contact | |

|---|---|---|---|

| Fuzzbass | USA | fuzzbass "at" verizon.net | |

| Elmigel | USA | Pete.hartman "at" gmail.com | |

| Dave.H | USA | ishkabbible "at" gmail.com | |

| LED-man | Europe/worldwide | check my Impressum |

Schematics:

http://thehumancomparator.net/wordpress/wp-content/uploads/2014/05/TTSHv3Schematics.pdf

you find the known erros/issues in "the tabs on top"

rev.3 Build Guide

rev.3 Quick build guide ( thanks to Anthony A Flagg aka fuzzbass)

this guide is only for builders with TTSH experience, dont try it if you build a TTSH before, the guide contains a BOM with partnumbers too.

V3 quick build bom.xlsx (right click to "save as")

TTSH Trimming - calibration

Troubleshooting knowledge

i ran in some difficult errors in some TTSHs, here are my experiences

for unknown issues/Errors check this page: useful Documentation for Troubleshooting

| Knowledge number | symptom | Probable error source | Probability of occurrence | pre check | testing | workaround | fix | lessons learned |

|---|---|---|---|---|---|---|---|---|

| TTSH-1 | VCO bleed (usage of frequency slider from one OSC influenced other VCOs frequency or Frequency range isn´t good enough or screaming VCO - weird frequency / instable Frequency | LFO/VCO switch (LF switch) | 80% | insert a stable v/oct signal (doublecheck with other devices your v/oct signal) | press/push/wiggle the LF switch, if you hear or measure a better result -> | heat up the 6 switch pins | normally a resolder/heatup fix the issue | the switch pins must be soldered with other soldercore or better heated/other solder tip. |

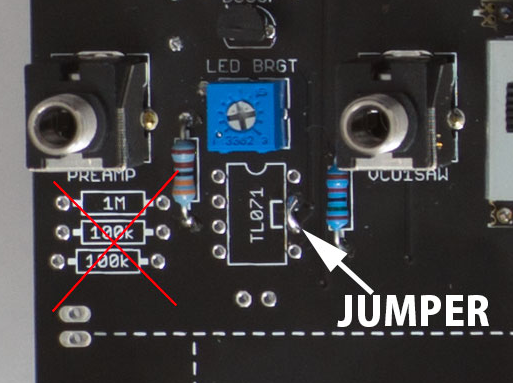

| TTSH-2 | all Slider LEDs are off | Trimmer, LED Driver | turn on the frontpanel (left hand) the LED trimmer clockwise, check on the frontpanel side on the empty IC socket next that you bridged pin 6+7 and no IC is plugged inside the socket. if not fixed: measure on the 5 pole powerheader all voltages | n/a | dont forget the jumper/bridge on pin 6-7 | |||

| TTSH-3 | few Slider LEDs are off | Trimmer, LED Driver | 50% | turn on the frontpanel (left hand) the LED trimmer clockwise, the TTSH LEDs are connected in 6? chains and in each chain are all slider LEDs in series - so you must check the correct LED polarisation (you can see the cathode/anode without demounting) | swap the LED to correct orientation | dont trust machines/roboter | ||

| TTSH-4 | all VCOs dont work | VCO 4027 boards | 10% | are the VCO subboards correct mounted ? (check the board connectors) are the CA3046 ICs inside ? check the soldering of the board connectors | solder all VCO conenctor pins before mounting the silders, add the CA3046 while mounting the connectors to the subboards | |||

| TTSH-5 | cant get a VCO sine wave in trimming/calibration process. (you get only a triangle) | VCO-2 section | 80% | check OP-amp orientation check J-FET (2N3954) instead 2N3958 | oscilloscope shows at the TRI out a Triangle - if not fix it before. | check the symmetry at first for the triangle, use gain to setup 10v then use the offset to bend the triangle spikes - they must form a corner in combination with purity. setup again 10v. its not a easy job - try it again - the trick is the combination of offset and gain not the purity ! | before you swap the 2N3954 try other ways as before by trimming the 4 trimmers , many guys swapped the working jfets.. | |

| TTSH-6 | ttsh works as a drone synth (by usage of cv/gate - the ttsh plays always sound instead of note on/off control) | 80% | check your silder settings - at the VCA output mixer - only VCA output instead of VCF or VCF and VCF. | read the usermanual | ||||

| TTSH-7 | by usage of the reverb function, a hum/noise occurs | 80 | see known issues - in/out silksceen is wrong check your noise is off check the wiring | use double or triple shielded cable with good RCA connectors, not the Synthcube cable "solution" the reverb distance must around 10cm or more from pcb to minimize the risk of EMV to the tank. check the grounding of signal input in the reverb, input and output must be grounded. check the cable with a rectifier test, check the soldering of the RCA connectors on the ttsh pcb. make sure you have the correct reverb type (grounding and impedance) | reverbs are very sensitive for EMV* | |||

| TTSH-8 | ADSR Release time opens the VCA and at 20fader way, the releasetime is too long | 50 | check all parts for correct value, check my pictures subpage | replace the 2N5460 or 2N4392 | test all trannys before soldering | |||

| TTSH-9 | sound from speakers - without OSCs enabled/installed | 30 | if the 10R resistors in the Amplifiers are hot or the MJE172 are hot, check the orientation of the MJE172 - the unlabeled side is at the white marker from the PCB. AND you have a short or defect opamp on your TTSH, which blows your MJE172 and the 10R resistors within 30seconds. you have to use a Bench power supply with current limiter, otherwise you freeze again the MJE172. you can cut at the 1UF elks the 6 pol power header - and connect it later with PC jumpers or use resistors legs to bridge the -15715V rails. | |||||

| TTSH-10 | power separation - in case of POWER FAILURES or shorts | use a Labor bench with current limiter. | separate the Sections, by cutting the traces. | |||||

| TTSH-11 | reverb doesn't work BL2AB3C1B | connect a cable from the black cable from left to the black cable on right side |

Best Practise:

| ID | TIP | reason |

|---|---|---|

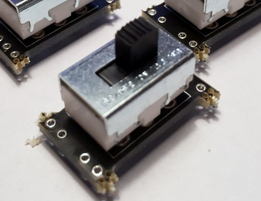

| 1 | when you have finished the build, move 2-3 times every slider | often the sliders cause some issues, they hang - only when you have moved the sliders 2-3 times they start to normal work |

| 2 | use Anti Rotating washers for the 5 nuts at the component side of the PCB | |

| 3 | do not trust every information regarding an audio path upgrade or subs. for the LM301 | you can always use: LM101, LM201 too - they have a better temp. stability than a LM301 they are also available in SMD package and works great. if you want an audio path upgrade, contact me and you get an offer. I do not share my secrets because some companies copy this ideas for his cheap clones. I spend few days and a lot of money in testing different opamps (which mostly need addional part changes on the pcb) |

| 4 | MODIFICATION | "Essential" Gatebooster Mod. VCF decoupling 1uF or more "my standard" Essential plus: Electronic switch mod AR MOD ADSR Switch Audiopath upgrade 1% matched capacitors in VCF 1% 680pF Styrene in VCO High temp. drift OPamps in VCO Highend: Essiontial plus "my standard" plus: Waveshaper MOD with subosc. some additional part changes - PSU passive cooling blocks Balanced driver with XLR |

| 5 | why not install the MIDI mod ?? | you have a half modular system - a intern MIDI gives you only the option to connect internal 2 CV connections. if you use a Kenton MIDI Standalone Interface (PRO SOLO MK2 or 3 etc ) - you can patch to every jack you want ! like the Ringmodulator or VCA etc... |

| 6 | why not install the VCO SYNC option ? | the mod isn't very easy for beginners or amateurs, the most users have problems with soft sync (when the SYNC is off) and many users blown the VCO SUB boards Transistors, which are not easy to replace. ( I have spare pcbs ) and if you install the Waveshaper board your risk of some VCO/EMV bleeds are bigger than before. The main reason is the sound, there's not a big difference in sound between a Ring MOD sound and a SYNC sound !!! |

Gallery

check also the rev.3 buildguide pictures with HQ pictures ( thank you Björn Verbruggen)

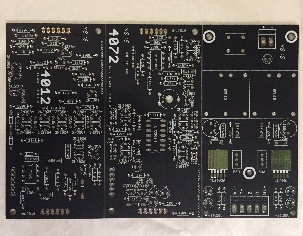

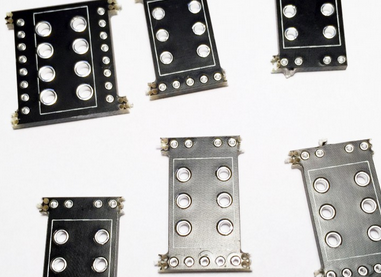

|

|

|

|

|

Stats

3 Comments

user-a5bb6

In the REV8-v1.2 BOM, the 2N5087 and BC558B on the 4072 filter are also listed as 2N3906. Is the 3906 a typo? An improvement? Or just cheaper and works just as well?

Also, looking at the PCB, there is no BC558B on there. Does row 11 on the "Semis" tab refer to the BC558B on the 4012 filter?

LED-man

3906 = 2N3906, BOM was updated.

Björn Verbruggen

Thanks Patrick for this great source of information and feedback!