Here are some important Issues and Fixes from the first batch TTSH pcbs (delivered around March 2014)

...

update 01.October 2014 VCO2/VCO3 bleed fix

(page links/anchors)

- pcb silkscreen failure for powersupply

- Hum issue on Speaker and more

- Noise "distorted"

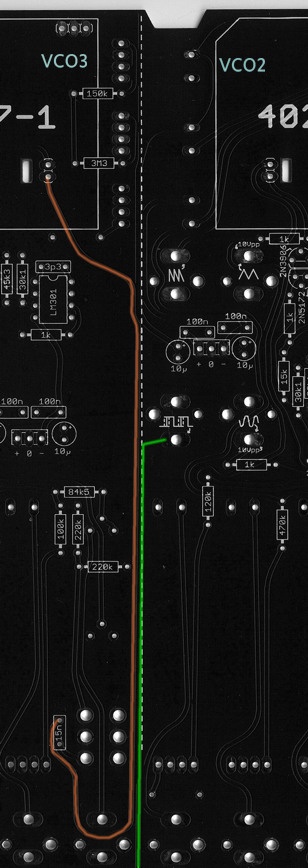

- Clock bleed on VCO pitch

- wrong Silkscreen for matched pairs

- wrong Silkscreen or polarity for Capaciator C20

- VCO Bleed - Regulator

- not all LEDs are working

- LED Dimming Fix

- VCO2-VCO3 Bleed fix

...

Solutions:

= tested

= untested

FIX for pcb silkscreen failure for powersupply

...

Option A: the easiest way is the usage of a BC337-16 with folllowed orientation, there´s no need for addional parts.

Option B (from nordcore)

leave out the 2n5172 - use a bc337-40, - bend right leg to top, solder a 10K resistor in series to the 1uF cap.

...

FIX for wrong silkscreen or polarity for capaciator C20 in RINGMOD section  valid

valid

| Anchor | ||||

|---|---|---|---|---|

|

change the polarity of C20 10µF elecrolytics (its the right hand capaciator)

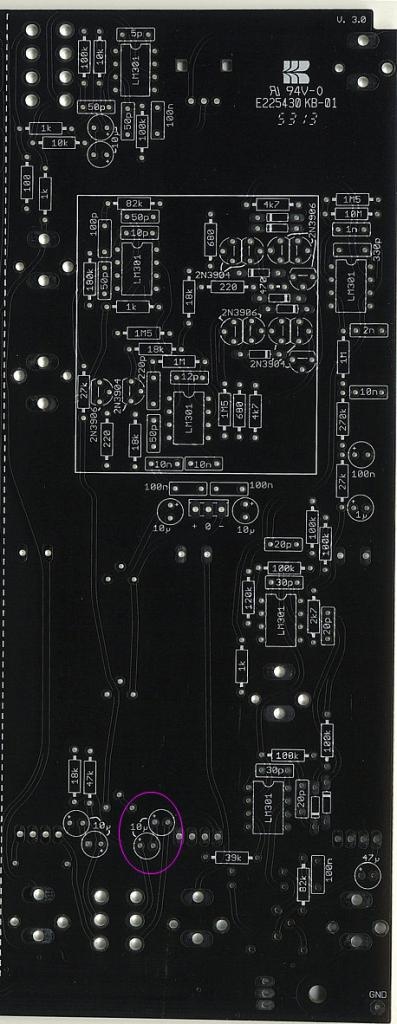

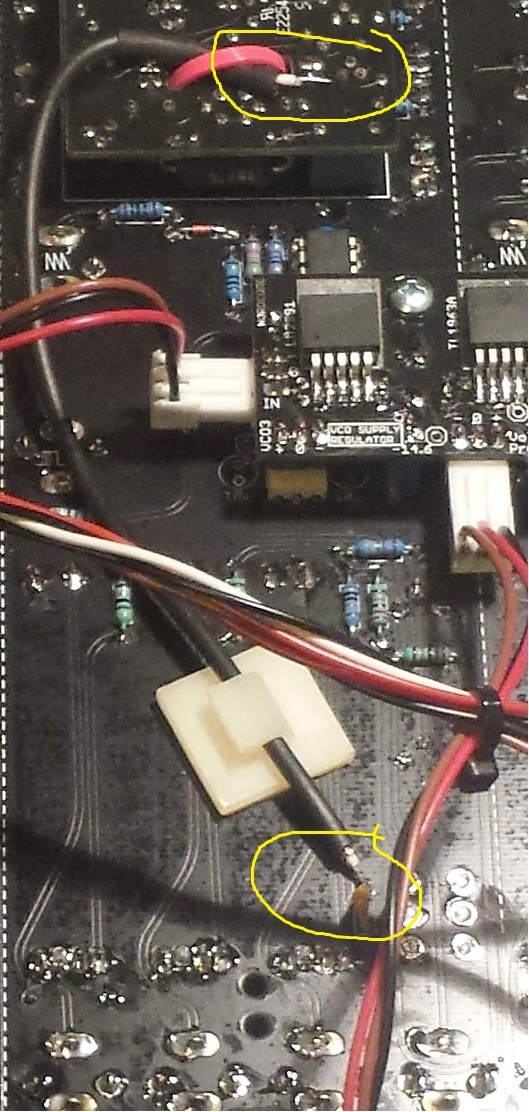

VCO Regulator:

| Anchor | ||||

|---|---|---|---|---|

|

...

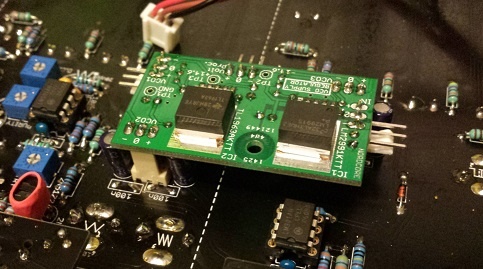

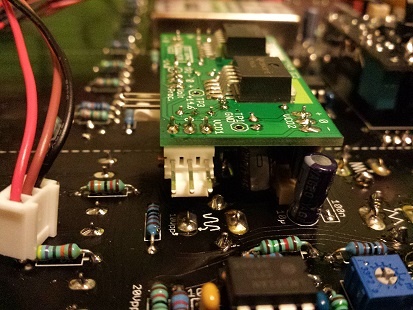

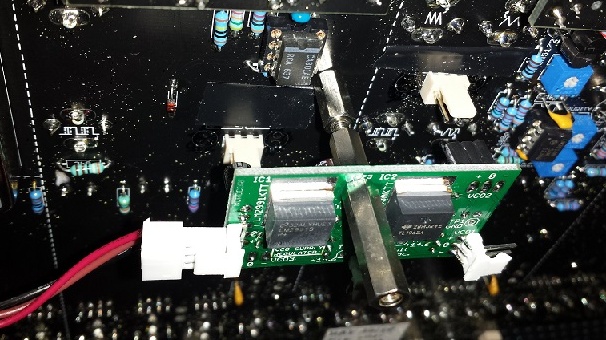

- build the VCO regulator

- desolder or cut the MLCC 100N from the power inputs on all 3vcos and from voltage processor, the 10uF caps can leave out too (but its okay to have this)

- drill a hole in pcb to mount by a 10/12mm spacer the pcb.

- put a further spacer on the 10/12mm spacer for calibrating the VCO regulator (dont connect the regulator to the vco header yet.

- connect only power input to regulator and set it to 14,6V (TP1+ TP2, TP1+TP3)

- unmount the second spacer and place the regulator in MTA header for final calibration/further tesing/building.

Issue: not all LED´s are working Anchor LEDs LEDs

| LEDs | |

| LEDs |

...

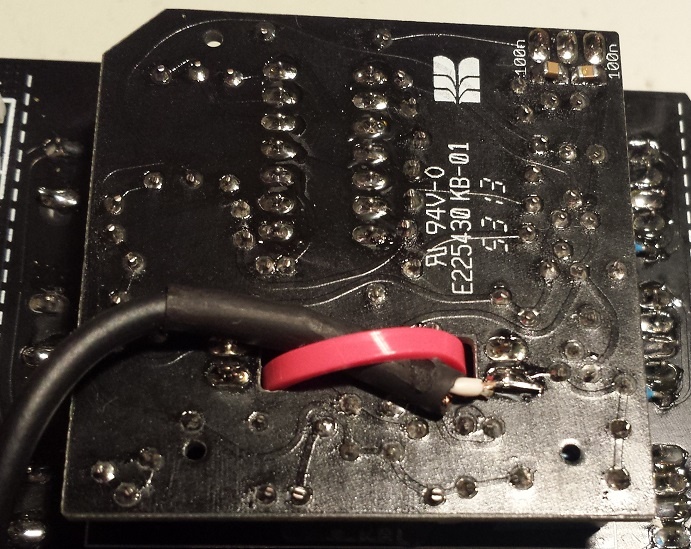

wire a ground to shielded cable shielding