Projecttitel: TTSH rev3 buidling guideStatus:  Startdate: 21.Dec.2016Duedate: 31.Dec.2016 last update 19 Feb 2017: known Issues - clock/s/h resistor

update 12.Jan.2017 Mouser Link updated update 13.Jan. 2017 Major bug found update 15.Jan. 2017 Excel list Slider quantity corrected update 16.Jan. 2017 Major bug update for jacks in total 3 jacks. update 18.Jan.2017 BOM excel list - added a "approved row", website improvements update 26.Jan. 2017 multiturn trimmer for v/oct improvement (optional), Noise transistor bug/improvement added from rev.1/2 guide, update early february Mouser BOM updated (bypass vco capacitors, VCF4072 capacitors.)Excel list updated with switches. |

|

due to changes in my webhosting (rootserver) costs for RAM/Backup and my worktime in Adminstration of the Server & Web Application Server it would be very helpful to use my paypal gift function, thank you

<form action="https://www.paypal.com/cgi-bin/webscr" method="post" target="_top">

<input type="hidden" name="cmd" value="_donations">

<input type="hidden" name="business" value="percysworld@web.de">

<input type="hidden" name="lc" value="GB">

<input type="hidden" name="item_name" value="DSL-man">

<input type="hidden" name="no_note" value="0">

<input type="hidden" name="currency_code" value="EUR">

<input type="hidden" name="bn" value="PP-DonationsBF:btn_donateCC_LG_global.gif:NonHostedGuest">

<input type="image" src="https://www.paypalobjects.com/en_US/i/btn/btn_donateCC_LG_global.gif" border="0" name="submit" alt="PayPal - The safer, easier way to pay online!">

<img alt="" border="0" src="https://www.paypalobjects.com/de_DE/i/scr/pixel.gif" width="1" height="1">

</form>

|

|

This guide is complete yet ( last update on 18.Jan.2017) please check my rev.2 build guide and hardcorebuildguide, gatebooster pages, that gives you more infos and knowledge.

the TTSH project isn`t for beginners !

Feel free to register a account for free, you can comment, export pages, you stay informed with pageupdates by email. send messages to me and other users with the share page function ( in top right corner)

you can send me a message if you want edit my pages, i´m looking for supporters.

further i´m looking for authors too, please contact me

|

Table of Contents

Trusted Builders:

| Name | Region | Contact | |

|---|

| Fuzzbass | USA | fuzzbass "at" verizon.net | |

| Elmigel | USA | Pete.hartman "at" gmail.com | |

| Dave.H | USA | ishkabbible "at" gmail.com | |

| LED-man | Europe/worldwide | check my Impressum | |

Schematics:

http://thehumancomparator.net/wordpress/wp-content/uploads/2014/05/TTSHv3Schematics.pdf

BOM: (Bill of material)

Synthcube left fullkits and partial kits

new BOM as Excellist BOM-list-TTSH REV8-v1.3.xlsx the lists includes all parts. (update 18.january 2017 approved section added)

The shared mouser basket from thehumancomparator is wrong (22.Dec.2016)

(this Mouser basket was provided in the 'order' eMail)

https://www.mouser.de/ProjectManager/ProjectDetail.aspx?AccessID=234c0 9ed60 old link from Jon

http://www.mouser.com/ProjectManager/ProjectDetail.aspx?AccessID=6CEDD31990 new Mouser link from me, improved see notice field for quantity "order 10"

order the 100K resistors, 2N3906, 2N3904, 1N4148 from a local dealer to save money, make sure the 2N3904/2N3904 is from tape - for better transistor value matching.

dont miss to order the parts for the gatebooster too.

old Printable BOM as listed, (rev.2 plus additional list for filter and psu)

ttshv2BOM.pdf (mainboard pcb) - i update the list in next 2 days. (remove the above listed SMT chokes and replace with chokes from SecondFilter_BOM)

4027v2BOM.pdf (vco boards)

TTSHrev3_SecondFilter_BOMv1.1.pdf (filter board) please use matched pairs 4 pairs of 2N5087 and only matched pairs for 2N3906/2N3904 (exept the single trannys)

for the rare parts, please check thonk.co.uk

if you need matched pair trannys or single tested trannys like 2N3954/8 or others, please contact me.

further i offer a survival kit

(link to my rare parts/survival page)

dont miss to order (if you only use the mouser basket)

Speakers: Visaton SC8 (reichelt.de, tme.eu)

reverb tank https://www.banzaimusic.com/Belton-RBL2AB3C1B.html see known issues for wiring

RCA/Chinch cable 0,5m - 1m (double or triple isolated/shielded otherwise you gets hum issues)

DC Powersupply 12V DC/1,5A - 24V/1A DC works, middle pin is + (5,5mm/2,1mm size)

Cable for Power wiring and Speaker wiring (1mm² diameter for power, 0,5mm² for speaker)

13 x 12mm Spacer M3, black flat Screws for frontpanel, screws for speaker at the rear and spacermounting, washers, nuts, cable shrink, silicon for matched pairs or glue the trannys together

1 x 10mm spacer + washer for filtercard mounting (ignore the second hole for a spacer in VCF section)

3x long spacers to mount the powersupply (25mm-50mm preferred to minimize the risk of EMV issues )

as stated above, the project is NOT for beginners nearly all professional builders have standard resistor and capacitor values at home (if the BOM miss a few standard parts like a 100K resistor) |

Known Issues

- Major Bug: Description: at the Frontpanel pcb side you find some "VIAs", at the VCO 3 section the jack S/H , VCO2 section the jack ADSR, VCA section the jack Ringmod, has a via with 15V, the metalcase of the jack is connected to ground and you run in a short between ground from the jack and 15V from the via, there are 2-4 other jacks with vias too.

check each pcb installation site for VIAs before mounting the jacks.

Solution: file down the jack at the position of the via (1mm is fine) or cut it down

- Improvement: Powersupply Board - turn the 2pol MTA156 header if needed - otherwise the power input cable is above the powersupply.

confirmed, its not in every use case needed confirmed, its not in every use case needed

Minor Bug:Main board – Missing trace from V- to header. (copyright of picture for thehumancomparator.net )  confirmed

Minor Bug: 4072 VCF missing trace pin 4 on LM1458 to -14V (use shrink tube for isolation)  confirmed

Minor Bug: 4012 VCF Board — BC558 must be installed backwards, schematics show Ermitter to 23k2 resistor in rev.7.2 (v2)  confirmed

- Minor Bug: for all 2N3958 and 2N3954 change 2 pins like this, cross the both pins - use shrink tubing for one pin for isolation.

confirmed confirmed

- Improvement for build: or the Filtercards use flat electrolyte capacitors, check the height of all parts - if needed use other headers, check this for both Filtercards before you solder the headers, if needed place the 47pf(50pf) MLCC capacitor (on the mainboard) on solderside of the pcb)

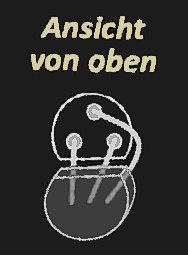

on my first build i used a 10mm spacer but i prefer the usage of 12mm spacers, (by usage of 2 spacers - its needed to cut on the VCF out jack at the bottom some metal and you need a flat screw, in result one spacer is enough  ) )

- Minor Bug: by usage of the banzai reverb tank, run in the reverb tank a wire from ground to ground on the RCA connectors to ground output and input

Minor Bug: turn 180degrees on the mainboard the 5pol MTA156 power header, otherwise the power cable is to the wrong side and maybe you run in trouble with your case/cabinet size. the picture shows the correct mounting:  - Minor Bug/improvement: use a BC337-16 instead 2N5172 in the noise section more Details here (you don't need further mods)

11. Medium bug - the Clock LED driver (BC337) becomes hot - affect the functionality in some cases. change the LED driver resistor LED-R17 from 220R to 1K ( its located at the Solderside bottom right, near the Clock fader)

|

rev.3 Build Guide

This guide is for users with experience in SDIY, you need a scope and a frequency counter, DMM/DVM/LCR-Meter) i dont share infos about polarity of capacitors, this basics skills are required, otherwise feel free to ask me for a assembly service. (check the trusted builder list) please use a fume extractor. its needed to solder 6 SMT caps in 0805 format and 2 SMT power regulators. this guide is a best practice guide, i´m not responsible for failures/malfunctions/defects. - lets start with the powersupply board - add all needed parts on the pcb, start with the two SMT power regulators.

there is one missing part (a dual choke) - please use wire links here or resistor legs

turn the 2 pol MTA header as described in the picture

if needed - wash the pcb carfully on the solderside

testing/trimming: use a 18-24V DC powersupply for input and set the output to 15V/-15V by usage of the both trimmers

measure between -V and 0 and +V and 0

- Mainboard PCB - place all IC-Sockets ( tin one ic socket from top, place the ic socket and heat the ic socket pin - the socket drop in place

on the rear side of the PCB is for the LED driver a ic socket - we dont use this one - dont solder a ic-socket here ! see step14 - best practise - begin with the "most use values" and end with the value range Mainboard PCB - start with 100K resistors, 10K, 1K, 1M, 100R (reverb), 10R (Amp) 10M (top right)

if done - 47k, 4k7, 470K, 4M7, – 22K, 220K, 220R, 2M2, 33K, 3M3, 330K... — 30K1, 680R, 68K, 68K1, 680K... ..... and all other

please remember: on solderside are few resistors too - on VCO 4027 boards and filter boards too - its your choice to leave it for later or assembly it yet too (i prefer later) - Mainboard PCB - place all rectifiers 1N4148

- solder from top all parts

- cut the resistor and rectifier legs from bottom side

- place all MLCC caps and solder from top

- place all polyester/polypropylen caps - bend the legs from top

- add all transistors in place and solder one pin from top -(except the 2N3954, both 2N3958 - if you cant test this, use a milled IC-socket and cut the pins out - use this as socket)

- turn the pcb and solder all pins. (no switches, no fader, no jacks, no pot, no trimmers)

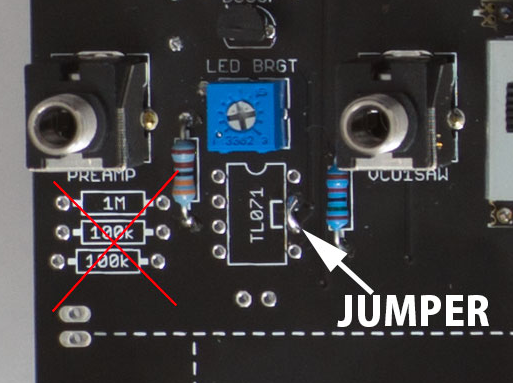

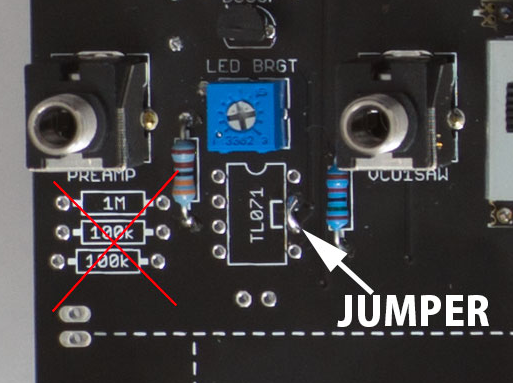

- you find on solderside few resistors - but take a look at step 14 - you don´t need the 3 resistors for the LED driver ( LEDs works too)

- wash the pcb 2-3 times if needed, i use Ispopropylen alcohole

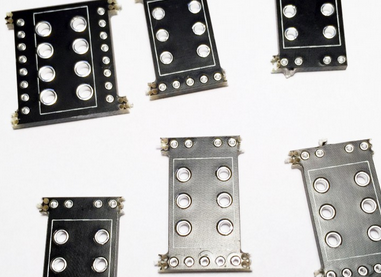

- make a breaktime/pause yet - the pcb needs time to dry - if you dont need a breaktime/pause - assembly the filterboards and 3 VCO 4027 boards - wash the pcbs too, make sure you use flat 10uF electrolyt capacitors, use c0g, polypropylen or silvamica for the 680pF cap, don`t mount the connectionsheaders yet

- on the PCB solder side, there is ic socket for the LED driver (near the multiples) its needed to bridge with a resistorleg the middle pins

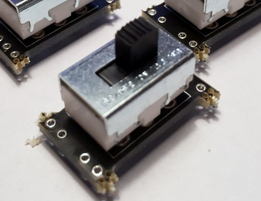

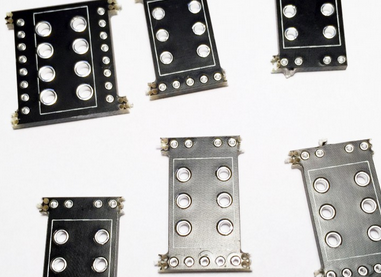

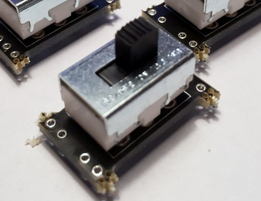

- Mainboard pcb: its time to add all other parts on the pcb - i prefer multiturn trimmers for the VCO V/oct trimmers 20K or 25K, but remember this can´t mounted on the frontpanel pcb side due to sizing, you have to open your TTSH for trimming the VCOs, begin with trimmers, faders - for faders keep attention on correct pcb side, best practise for faders: turn the pcb upwards on your desk add 4 faders in place, one hand holds the faders with other hand bend the faderpins with a flat screwdriver, solder all faders, add the Gain pot on top and solder them.

- add the header/sockets for VCOs, Filtercard - best practise: mount each header in socket - put them in place on the pcb - add the vco pcb on top and solder at first on top (sub vco pcb to header) not the header to mainboard pcb.

then start the soldertask for the other side. - check on your pcb other parts: you need to assembly few 2pol, 5pol MTA headers (gate/trigger/power) solder in the RCA jack for reverb, you have to add a 3 pol MTA header to powering the optional Gatebooster and/or TTSH sync board , on each section you find 6 pol holes.

- now its nearly done - doublecheck all solderpoints, missing resistors,caps..

- add the 13x 12mm spacers for speaker to pcb, dont fix it very strong - we need to align this in step 22

- you find on the pcb on left bottom near the speaker hole switch adapter pcbs, cut them out and place they behind the switches

- setup all 81jacks in place, don`t solder the jacks yet

- place the frontpanel on the pcb/spacers - fix it with screws - if needed align the spacers

- add on each corner a washer and nut to a jack and at the bottom/near of the voltageprocessor

- at this time you need four hands if possible.. to turn the pcb without loosing jacks

- solder at first the jacks from step 21

- check the switch posistions, align it and solder 1-2 pins (middle pins), check again the positions, if needed correct it.

- if the alignment of all parts are fine, solder all swicthes and jacks

- if needed clean with eartips and isopropylene the solderpoints of silder/switches/jacks

- add the 3 VCO 4027 modules and one filtercard in place.

- time for wiring: speakerwiring/headphone,

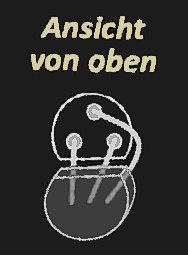

Wire first to speaker , then to headphone jack For the left amp : Connect pad L to left speaker (+ ) connect the negative speaker out to Headphone Tip, connect the Tip Switch back to the L connector gnd pin. For the right amp : Connect pad R to + on the right speaker and the negative on speaker goes to the Ring on the headphone jack, the Ringswitch is connected to gnd next on R connector And finally connect sleeve pin on jack to ground somewhere on board. (external gate ground is good choice) So when headphone is inserted it breaks the connection to the speakers.

- unmount the panel, add 3 long spacers (20-50mm to the 3 holes near voltage processor - the stands are used for the powersupply yet - mount the psu pcb on top), remount the panel

- wire the powerswitch between + line and the powersupply pcb input

for power between powersupply and mainbaord - doublecheck the polarity, |

TTSH Trimming - calibration

Troubleshooting knowledge

i runned in some difficult erros in some TTSHs, here are my experiences | Knowledge number | symptom | Probable error source | Probability of occurrence | pre check | testing | workaround | fix | lessons learned |

|---|

| TTSH-1 | VCO bleed (usage of frequency slider from one OSC influenced other VCOs frequency or Frequency range isn´t good enough or screaming VCO - weird frequency / instable Frequency | LFO/VCO switch (LF switch) | 80% | insert a stable v/oct signal (doublecheck with other devices your v/oct signal) | press/push/wiggle the LF switch, if you hear or measure a better result -> | heat up the 6 switch pins | normally a resolder/heatup fix the issue | the switch pins must be soldered with other soldercore or better heated/other solder tip. | | TTSH-2 | all Slider LEDs are off | Trimmer, LED Driver | | turn on the frontpanel (left hand) the LED trimmer clockwise, check on the frontpanel side on the empty IC socket next that you bridged pin 6+7 and no IC is plugged inside the socket. if not fixed: measure on the 5 pole powerheader all voltages | n/a | | | dont forget the jumper/bridge on pin 6-7 | | TTSH-3 | few Slider LEDs are off | Trimmer, LED Driver | 50% | turn on the frontpanel (left hand) the LED trimmer clockwise, the TTSH LEDs are connected in 6? chains and in each chain are all slider LEDs in series - so you must check the correct LED polarisation (you can see the cathode/anode without demounting) | | | swap the LED to correct orientation | dont trust machines/roboter | | TTSH-4 | all VCOs dont work | VCO 4027 boards | 10% | are the VCO subboards correct mounted ? (check the board connectors) are the CA3046 ICs inside ? check the soldering of the board connectors | | | | solder all VCO conenctor pins before mounting the silders, add the CA3046 while mounting the connectors to the subboards | | TTSH-5 | cant get a VCO sine wave in trimming/calibration process. (you get only a triangle) | VCO-2 section | 80% | check OP-amp orientation check J-FET (2N3954) instead 2N3958 | oscilloscope shows at the TRI out a Triangle - if not fix it before. | | check the symmetry at first for the triangle, use gain to setup 10v then use the offset to bend the triangle spikes - they must form a corner in combination with purity. setup again 10v. its not a easy job - try it again - the trick is the combination of offset and gain not the purity ! | before you swap the 2N3954 try other ways as before by trimming the 4 trimmers , many guys swapped the working jfets.. | | TTSH-6 | ttsh works as a drone synth (by usage of cv/gate - the ttsh plays always sound instead of note on/off control) | | 80% | check your silder settings - at the VCA output mixer - only VCA output instead of VCF or VCF and VCF. | | | | read the usermanual | | TTSH-7 | by usage of the reverb function, a hum/noise occurs | | 80 | check your noise is off  check the wiring | | | use double or triple shielded cable with good RCA connectors the reverb distance must around 10cm or more from pcb to minimize the risk of EMV to the tank. check the grounding of signal input in the reverb, input and output must be grounded. check the cable with a rectifier test, check the soldering of the RCA connectors on the ttsh pcb. make sure you have the correct reverb type (grounding and impedance) | reverbs are very sensitive for EMV* | | | | | | | | | | | | TTSH-8 | ADSR Release time opens the VCA and at 20fader way, the releasetime is too long | | 50 | check all parts for correct value, check my pictures subpage | | | replace the 2N5460 or 2N4392 | test all trannys before soldering |

|

Gallery

check also the rev.3 buildguide pictures with HQ pictures ( thank you Björn Verbruggen)

Stats